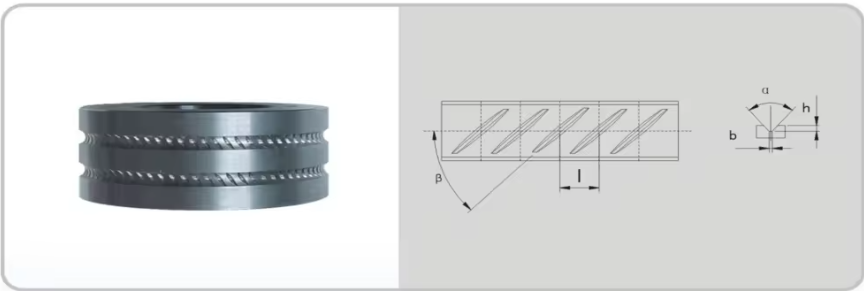

| Item name | HR40 Tungsten Carbide Pre Finishing Ring Roller Cemented Carbide Hot Rolling Block |

| Grade | HR30 HR40 HR45 |

| Hardness | 83 HRA |

| Cobalt % | 17%-23% |

| grain size | 1.6-2.4 |

| Usage | Hot rolling mill to make rebar |

| Logo | HR Carbide |

| package | standard sea worthy |

Our company independently developed carbide grades HR30 HR40 HR45 for hot rolling rollers: with high temperature resistance, high pressure resistance, high hardness, high wear resistance, efficient production and high economic benefits. The specific performance is as follows:

1. The hardness range is 82HRA-84HRA, with excellent wear resistance, and can be used for a long time without frequent replacement.

2. High shape and size accuracy, can maintain a stable shape and position, ensure the accuracy and consistency of the rolling process, and improve product quality.

3. It has excellent high temperature and high pressure resistance, can withstand high temperature and high pressure during rolling

4. Efficient production and high economic benefits

In addition, due to the high thermal conductivity and good heat dissipation effect of carbide hot rolling rollers, they are more resistant to corrosion and cold and hot fatigue than tool steel rollers

Golden Airlines advantage

Customized service

Equipment field personalized mold to map to sample professional customization

Map evaluation

Calculate the production feasibility of the measured drawings and help optimize the mold design

Fast response

6*12 hours online service, 24 hours timely response

Special personnel docking

One to one VIP service, full tracking

Problem solving

Industry technology exchange, online experts answer questions

After-sales service

Perfect after-sales service system, professional

Our factory

Q&A

Can I have my own custom product?

Yes. oem and odm can be provided, including design, logo, packaging, etc.

What is the minimum order quantity?

It depends on the product.

What are the terms of payment?

Wire transfer or letter of credit, Western Union, Alipay, etc.

When is the delivery time?

Inventory orders within 7-15 days, for oem and odm orders, the specific time depends on the actual situation.

HR40 Tungsten Carbide Pre Finishing Ring Roller Cemented Carbide Hot Rolling Block

Product category:

Tags:

Related products

HR40 Tungsten Carbide Pre Finishing Ring Roller Cemented Carbide Hot Rolling Block

Tungsten Carbide Cold Rolling Ring TC Roller